As the old adage goes, time is money. The more production you can squeeze out in a period of time, the more money you make, right? As per the old saying, ‘time is money’; however, with improve productivity in manufacturing industry, it is inversely proportional to one another. The higher the production in a stipulated frame of time, the more one gets to make it and manufacturers, across the world are in a continuous process to pursue efficiency in production through consistent increase in machine output, thereby meeting newer profitability heights and maintaining competitiveness.

And productivity in manufacturing is dependent on a number of factors – it is a combination of skilled employees, competent equipment and resourceful processes. To increase throughput without the need for sacrificing quality involves a detailed scrutiny of the existing practices, making adjustments, however minor, to systems, constant skill upgradation for employees and enhancing the efficiency of equipment that are used for the generation of parts and components.

The fundamental nature of enhancing manufacturing productivity can be engaged through:

• Information: the accurate capture of information through the identification of losses

• Focus: the identification of priorities through the use of that information

• Action: ensuring action that is deliberate, methodical and sustainable for the long-term

• Focus: the identification of priorities through the use of that information

• Action: ensuring action that is deliberate, methodical and sustainable for the long-term

Blurb starts

The total productive maintenance is the most crucial element for lean manufacturing, and includes an useful efficiency metric – the overall equipment effectiveness, thereby measuring the percentage of planned production time to indicate the ratio of quality throughput, as quickly as possible, without any down-time.

Blurb ends

There are a number of alternatives today that could help to reorganize the way you work by reducing the struggle of improving productivity, increase incentives that could drive up numbers. These have been variously explained, below:

• Examine the existing workflow

• Update business processes

• Invest continuously into the skill upgradation of employee skills

• Establish realistic expectations

• Procure smarter equipment tools

• Ensure an organized process

• Encourage team work

• Update business processes

• Invest continuously into the skill upgradation of employee skills

• Establish realistic expectations

• Procure smarter equipment tools

• Ensure an organized process

• Encourage team work

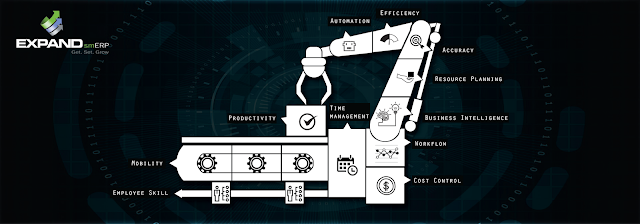

A significant initiative that could ensure effective business management at the manufacturing level is the effective implementation of a robust Enterprise Resource Planning (ERP) system. Some of its operative areas include: sales, finance, e-commerce, warehouse management, purchase, HRMS, CRM and inventory management.

The implementation of ERP with the objective of improving manufacturing productivity is a vital requirement in the industry, today. To ensure the enhancement and seamless business management through advanced ERP systems are sure to provide invaluable benefits to manufacturers who seek cost reductions, growth management, enhanced efficiency and robust process that are streamlined with the objective to gain a competitive business advantage. Some of the benefits of implementing an effective ERP system that are aligned to the business goals are as follows:

• Stay ahead of competition

• Save money

• Enhance productivity

• Increase growth

• Improve people skills

• Ensure mobility

• Augment business intelligence

• Save money

• Enhance productivity

• Increase growth

• Improve people skills

• Ensure mobility

• Augment business intelligence

Despite the benefits of implementing robust ERP tools for the effective business management, the simple deployment of ay software won’t lead to the achievements of organizational goals. There are a lot of research and dedication that needs to go into ensuring right software for the business. And once the right ERP tool is integrated, the results are sure to follow.

No comments:

Post a Comment

Thank you for your Comments.

ExpandERP Team