Every businessperson hopes to create a business that is profitable and scalable. However, instead of focusing on creating a robust business model with long-term sustainability, most end up working in the business with a gung-ho, hands-on attitude. And scalability doesn’t happen with that approach. What entrepreneurs fundamentally require is an opportunity to leverage and a prospect to scale-up.

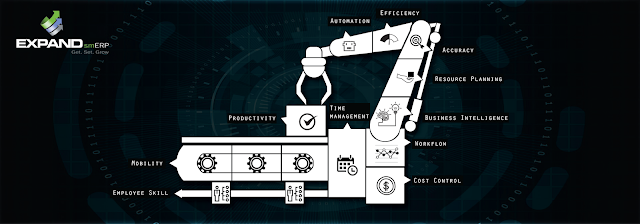

But it’s not just entrepreneurs but project managers and other professionals, who require a sustainable way to get smart, thereby manage the workload more effectively without losing on any time, money or energy. Automated business process management, is, undoubtedly the most efficient way to acquire consistent and accurate results, streamline tasks, boost operational effectiveness and ensure a smooth workflow. In short, business process automation is a sure way to eliminate all those unnecessary human interventions which could be erroneous, costly and time consuming. Moreover, the automation process can be implemented in any business across any industry.

Any business, no matter how big or small, should consider automation if it intends to stay and competitive, enhance operational speed, reduce errors, increase productivity, eliminate irrelevant steps, build volume, reduce waste, expand capabilities and reduce cost.

Although automated business process management could be a chance to revolutionize the way how any business works, businesses should understand the thoroughness of mapping out the project. And before implementing this process the management should perform a self evaluation in relation to business process management. Thus a business person or a project manager should first figure out the answers to critical questions, such as, ‘Is the organization ready to work smarter?’ or ‘Are the employees ready to move from the traditional working methodology of spreadsheets and files to a new system as a team?’, ‘Once automated, can the organization work with lesser manpower and still deliver products or services with same or better quality?’, etc.

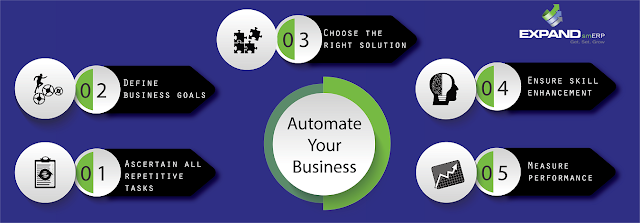

After the purchase of a workflow software for the automation of complex processes across business departments, it is also critical ensure that the software is perfect for the business and not just some means to merely provide the flaws in the existing system. To help with the preparation here are 5 steps to automate any business workflow:

The first step towards automating a business workflow is to ascertain all repetitive tasks. Flow charts of existing processes coupled with an excellent understanding of the workflow would be the right way to go about it.

Any business can be rendered unsuccessful without SMART goals and objectives. SMART goals encompass ‘specific, measurable, attainable, relevant and timely’ objectives that could optimize resources for productive tasks, reduce cycle time, improve throughput and should definitely be aligned to the existing workflow benchmarks.

The third step in the automation process would be to choose the correct workflow automation solution. While there are a plethora of automation software available in the market, it is crucial to choose the ideal fit.

Updating the skills of the users would be the next most significant thing in the automation processes. Neglecting it by resisting the development of the users can prove detrimental for the business.

The fourth step in this process is to measure the performance of the automation. While putting the system on live, perhaps a test run would be sufficient for the users to smoothen out any kinks in the armour.

There are a number of steps that may be adopted for the successful implementation of the workflow. However, there are a few do’s and don’ts that should be kept in the mind. Instead of choosing mission critical projects that are heavily integrated with other software, managers should begin with divisions that involve lesser stakes. Thus it would be suffice to say that the automation of business processes will not only anticipate the needs of the existing workflow but also use the same to increase efficiency, provide visibility into business processes and reduces costs substantially.